If you want to operate Bobcat equipment effectively, you need to know what those little lights on your dashboard are trying to tell you. Whether you are an experienced operator or a new operator of these turbines, the warning lights are your equipment’s method of telling you if something could go wrong before it turns into an expensive problem.

After spending years of dissecting these symbols, I can tell, recognition can save you money, time and a lot of headaches. This guide will cover all the above, from a brief overview of the Bobcat warning light symbols, to more complex diagnostic codes, ensuring you keep your machine in tip-top shape and avoid those costly downtime scenarios.

Contents

- 1 The Most Common Bobcat Warning Light Symbols And What They Stand For

- 2 Color-Coded Alert Systems on Bobcat Machines

- 3 Warning Symbols Relating to the Engine

- 4 Hydraulic system warning lights

- 5 Methods to Read Bobcat Fault Codes on Various Models

- 6 How to Troubleshoot Bobcat Warning Lights

- 7 How to Prevent Seeing a Warning Light

- 8 The Future of Bobcat Warning Technology

- 9 The Safety Implications of Warning Light Symbols

- 10 Bobcat Warning Light Symbols FAQ

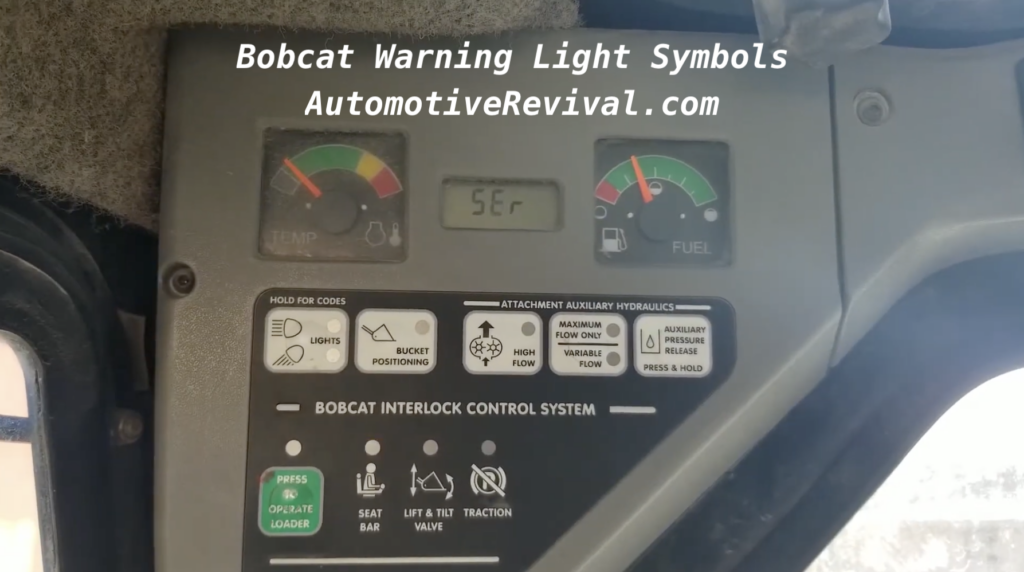

The Most Common Bobcat Warning Light Symbols And What They Stand For

These symbols have the highest frequency at the largest level, and need to be attended to as soon as their light is on.

Battery Indicator Symbol

If this light illuminates, the electrical system in your Bobcat is not getting charged. It may point to a failing alternator, loose connections or a dying battery. I ignored this light ONCE and was nearly stranded on a deserted construction site – lesson learned!

WARNING: Engine Coolant Temperature

This alerts you that the engine is overheating — an issue with grave implications that you must address promptly. Shut down and allow the engine to cool before inspecting coolant level.

Oil Pressure Indicator

Your engine needs lubricant, perhaps the most urgent warning. Failsafe – shut down immediately to minimize catastrophic engine damage.

Brake System Warning

This light indicates a problem within your braking system — including low fluid or worn pads. Never drive with brake warnings on.

Fuel Indicator Light

The most simple but still significant warning — you’re running out of fuel. On telehandler-style machines and M-series loaders, the M0909 code normally pairs with this light as well.

Color-Coded Alert Systems on Bobcat Machines

Colors tell you how bad the problem is, even before you recognize what’s wrong.

Red Warning Lights: Show-Stoppers

Red; stop all operations immediately. These are warnings that, if not heeded, could damage your equipment, or create hazards — safety hazards.

Yellow Warning Lights: Moderate Malfunctions

The yellow means caution that something needs your attention soon but you may be able to leave things as they are until you get to that task.

Blue and Green Indicators: System Operations

These colors are generally used to indicate normal operations, or activated features, not issues. They are informational, not warnings.”

Warning Symbols Relating to the Engine

These warnings keep the most important piece of your Bobcat, its engine, healthy and beating.

Engine Symbol Warnings

A generic engine light usually means the computer isn’t seeing something it wants you to scan and diagnose. Don’t brush this one off.

Oil Pressure Warning Lights

Unlike the primary oil pressure gauge, these may provide information on localized oil circulation issues in distinct engine zones.

Coolant Temperature gauges

These alerts indicate when your engine is operating at too high of a temperature or occasionally too low, both of which can negatively impact performance and longevity.

Hydraulic system warning lights

Your attachments and movement are powered by the hydraulic system – these lights are what helps keep it turning.

High Hydraulic Oil Temperature Indicator

Overheated hydraulic fluid becomes less effective and can cause seals and components to fail. This light warns you ahead of that event.

Only test data for hydraulic pressure drop indicators

Hydraulic Pressure Alert – These lights signify when your hydraulic system is not sustaining proper pressure, often due to leaks or pump issues.

Methods to Read Bobcat Fault Codes on Various Models

This approach lets you perform most of your work quickly and without any guesswork.

On touch screen equipped R Series models, touch on service codes to see active errors / code history. It also displays service schedules and records.

M2 Series Panel Access

M2 Series with deluxe panels: active warnings On default panels, touch the information button until you get to the screen with book symbol and wrench overlay.

Console and Instruments Panels

In older models, warning lights and symbols appeared on the instrument panel itself. Look at your operator manual to know what each symbol refers to.

How to Troubleshoot Bobcat Warning Lights

Steps to tackle these lights appropriately when they show up.

What To Do On Spot When Light Starts To Glow

First, assess the need for immediate termination (red warnings) and the ability to continue in safety. Make a note of the code number.

Resetting Warning Light Systems

For resetting maintenance reminders on M-series machines, press and hold the information button on the maintenance screen until it resets. Other codes might need to have the source problem resolved before they’ll clear.

When to Get Professional Help

In such case, it often needs dealer support as it’s a high level dealer level problem like H7404 Main Controller No Communication code. There are some issues that require special diagnostic equipment only professionals will have.

How to Prevent Seeing a Warning Light

Regular checks and maintenance prevent problems before they start.

Regular Fluid Level Checks

Daily check oil, coolant, and hydraulic fluid levels. Warning lights are triggered at low levels, and ignoring those can lead to serious damage.

Engine Performance Monitoring

Be wary of abnormal sounds, smoke or variation in performance. These usually come before warning lights and allow you to deal with problems early, before they get more serious.

Electrical System Maintenance

Maintain clean, tight battery connections. Correct electrical function is also necessary for many warning systems to work properly.

The Future of Bobcat Warning Technology

New tech makes warnings more useful and informative than ever.

DPF and SCR System Indicators

Modern Bobcats have emissions systems for which there are specific warnings, helping you ensure compliance and prevent damage.

Engine Derate Warning Lights

These more high-level alerts indicate when the system is reducing engine power to protect from damage due to issues the system has detected.

Monitoring Symbols for ActiveHydraulics

Most newer vehicles also have advanced hydraulic monitoring that will alert the driver of potential issues before they become problematic in performance.

The Safety Implications of Warning Light Symbols

Alarm lights are not limited to damage prevention; they are also operator safety measures.

Critical Safety Warnings

Some warnings cover conditions dangerous to operators, such as rollover potential or attachment failure5. You are never to ignore safety-related signs.

Key Performance Indicators for Operational Efficiency

Not all lights are there to warn you of problems; some help optimize performance. You learn these so you can work more efficiently.

Maintenance Reminder Symbols

The book with the wrench symbol reminds you of the scheduled service, which will help you avoid bigger problems through regular maintenance.

Bobcat Warning Light Symbols FAQ

Answers to your most frequently asked questions about Bobcat warning lights.

Can you reset warning lights yourself?

Some yes, but others need to fix the issue at the root.

What happens if several lights come on at the same time?

Handle red warnings first, yellows second.

Troubleshooting Tips

When in doubt, refer to your operator manual or Bobcat’s fault code guide. The company has an online searchable tool that lets you enter your machine’s serial number and the fault code for targeted instructions.

Maintenance Best Practices

Perform daily visual inspections prior to start of work. Keep your machine clean to avoid debris interfering with the sensors. Prevent warning lights from even appearing in the first place by servicing your Bobcat every 250-500 operating hours.

Leave a Reply